Seamless aluminum tube VS Welded aluminum tube

Seamless aluminum tube VS welded aluminum tube

Aluminum tubes are used in various industrial fields. Their advantages are that they are lightweight, corrosion resistant, low oxidation resistance, and have good formability. Commonly used aluminum tubes can be divided into two types: seamless and welded.

1. Seamless aluminum tube

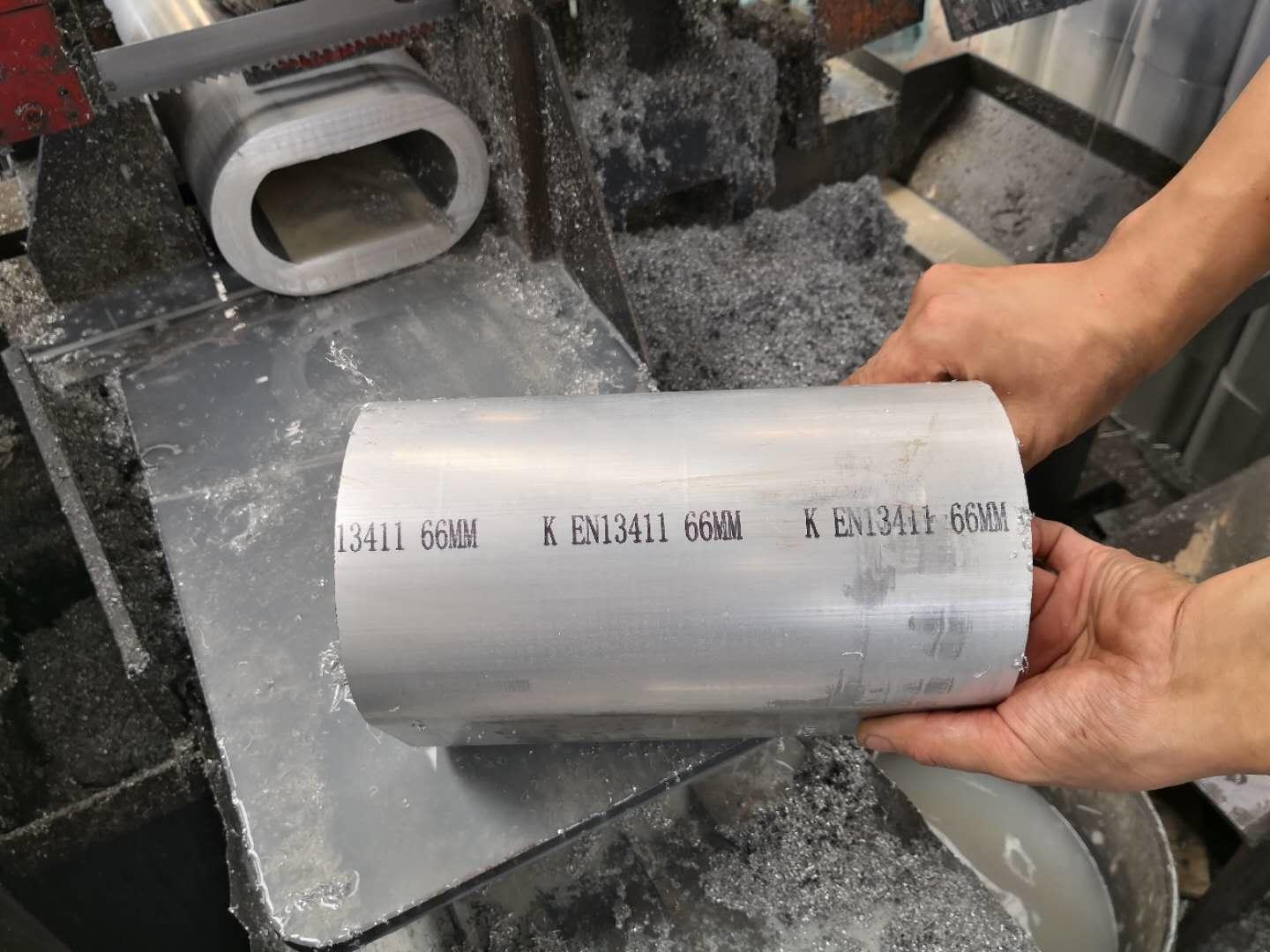

Seamless aluminum tubes are made by extruding a single piece of aluminum. During processing, the prepared aluminum needs to be heated and then extruded into a tube shape through a die in an extruder. The aluminum tubes produced in this way have a smooth surface and no welding marks. They have high-pressure resistance and are leak-proof and durable.

2. Welding aluminum tube

Welded aluminum tubes are made from two or more aluminum materials or extrusions that are joined together using various welding techniques, so welded tubes have visible seams and the cost is much lower than seamless aluminum tubes. There are often slight imperfections at the welded joints, which can cause leaks or ruptures under high pressure.

3. Seamless aluminum tubes and seamed aluminum tubes have their characteristics. You should choose according to the specific application to achieve a balance between cost and performance.

Seamless aluminum tubes are more expensive, have higher strength, are leak-proof and pressure-resistant, and can provide excellent corrosion resistance. Therefore, they are mainly used in industries that require hydraulic pressure, strict forming, uniform strength, and a more uniform appearance after anodizing. Seamed aluminum tubes are relatively cheap and very suitable for applications that require high strength and durability but do not necessarily require a high level of pressure resistance.

Seamless aluminum ferrule VS seamed aluminum ferrule

There are also some differences between the seamless aluminum ferrule produced by seamless aluminum tube processing and the seamed aluminum ferrule produced by welded aluminum tube processing. The comparison is as follows:

| Seamless aluminum ferrule | Seamed aluminum ferrule | |

| Material | 5051A aluminum alloy or 5051, 5052 | 6063 Aluminum Alloy |

| Processing methods | Seamless extrusion | Welding Process |

| Cost | The manufacturing process is complex, such as heating, extrusion, and drawing, and the cost is high | The manufacturing process is simple, relatively cheap and cost-effective |

| Is there a weld | No welds | With weld |

| Safety | safer | risky |

| Application | Lifting and hoisting, etc. | Door and window profiles, fishery markets, wire rope fences, etc. |

Conclusion

From the comparison in the above table, we can see that there is a big difference between the two.

In the field of lifting and hoisting, seamless aluminum ferrules are safer and more reliable than seamed aluminum ferrules, because seamless aluminum ferrules are produced by the requirements of EN13411-3 through a seamless extrusion process, with smooth surface and no weld line, so they are safer. Although the price of seamed aluminum ferrules is lower, for process reasons, weld lines will be formed during the production process, and the rigging made of it will risk breaking at the weld line during use.

For the sake of safe production, it is recommended that you use seamless aluminum ferrules.